GxP Lifeline

Transforming Life Science Manufacturing: The Strategic ROI of Smart Automation

"81% of manual data entries can be eliminated through smart automation in life science manufacturing."

That's not just a compelling statistic from MasterControl's recent "Maximize Life Sciences Manufacturing ROI Through Smart Automation Strategies" webinar—it's a game-changer for quality teams drowning in paperwork and manufacturers struggling with throughput.

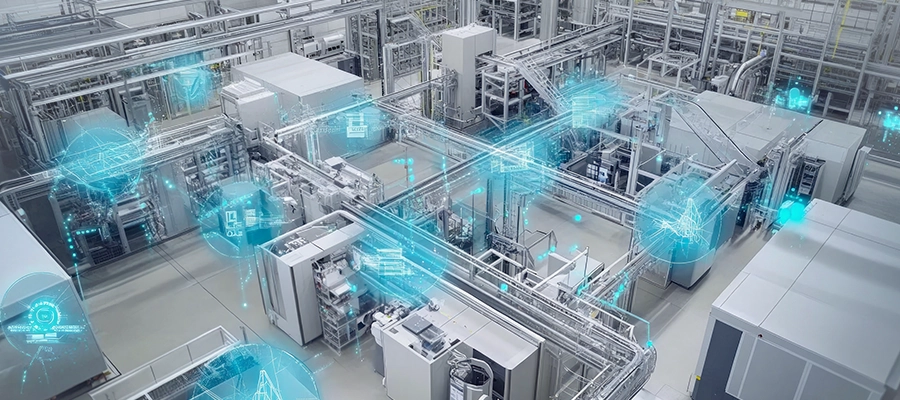

In today's competitive life sciences landscape, manufacturers face a familiar challenge: how to increase production efficiency while maintaining strict quality standards. Long lead times, manual processes prone to errors, and stretched resources continue to plague manufacturing floors across the industry. But there's good news—strategic manufacturing automation is revolutionizing how companies address these challenges.

The Current State: Manual Processes Are Holding You Back

Let's be honest about where most life science manufacturing stands today:

- The average batch record contains roughly 1,000 manual entries across manufacturing and packaging.

- Review and release cycles eat up 7-14 days.

- Error rates from manual data entry hover around 3%, creating a need for thousands of corrections.

- Quality teams spend more time reviewing documents than solving critical quality issues.

These inefficiencies hit your business where it hurts: delayed revenue recognition, bloated inventory costs, and worst of all, potential stockouts that affect patient well-being.

Higher throughput.

Lower error rates.

That changes everything.

Curious about the industry challenges driving the need for automation? Our on-demand webinar "Maximize ROI Through Smart Automation Strategies in Life Sciences Manufacturing" unpacks the problems and solutions with clarity and precision.

Bridging the Automation Gap

Despite all the technological advances we've seen in recent years, many life science manufacturers still operate with paper-based systems or basic "paper-on-glass" solutions that barely scratch the automation surface.

Modern manufacturing excellence requires something more inventive. True automation in life sciences means:

- Augmenting your team's capacity with digital tools that work.

- Eliminating unnecessary manual data entries for good.

- Building intelligent connections between your systems.

- Applying smart, risk-based approaches to quality processes.

Digitize batch records.

Shatter throughput records.

The Numbers Don't Lie: Your ROI on Automation

Let's talk real returns. The business case for smart automation in life science manufacturing isn't theoretical—it's backed by hard data:

- Simply digitizing batch records with embedded automation features eliminates or automates 54% of manual data entries.

- Adding barcode scanning and system integrations bumps up efficiency to 81%.

- Release times can drop by 90% or more with risk-based exception review.

- Manufacturing execution times cut in half.

- Review hours reduced by 43%-75%.

Want to see the full ROI analysis and real-world results? Watch our on-demand webinar where manufacturing experts break down the numbers that matter to your bottom line.

Beyond Efficiency: Quality That Improves Everything

While operational efficiency drives conversations about ROI, let's not forget what smart automation does for quality and compliance:

Error Reduction

By automating data capture and calculations, you're not just saving time—you're preventing mistakes. One manufacturer implementing comprehensive batch record automation avoided over 1.4 million potential errors (based on industry standard error rates).

Better Audits

With automated verification and complete audit trails, your audits become shorter and have fewer findings. Digital systems provide immediate traceability that paper simply can't match.

Smarter Risk Management

Smart automation lets you focus controls where risk is highest while eliminating unnecessary steps in lower-risk areas. It's not about more documentation—it's about the right documentation.

Discover how automation transforms quality outcomes. Our on-demand webinar showcases real examples of error reduction and compliance improvements that matter.

Changing Your Mindset: From Paper to Digital-First

Achieving impressive returns requires more than implementing new technology. It demands a shift in thinking. It's time for life science manufacturers to move from "paper-on-glass" to truly digital-first approaches.

Start by asking different questions about your current processes:

- What's the real purpose of collecting this data?

- Is manual verification truly necessary here?

- Can we capture this information automatically?

- Did we add this step after an audit observation?

- How can we apply risk-based thinking instead?

Too often, manufacturing processes become bloated with excessive checks following audit observations. A digital-first mindset challenges these approaches by properly assessing risk and using automation to optimize processes and control what really matters.

Ready to shift your thinking? Watch our on-demand webinar with industry experts who've successfully led digital transformations in manufacturing environments just like yours.

Real Results: Manufacturing Excellence in Action

The transformation from paper-based or basic electronic systems to intelligent automation delivers measurable improvements across key performance indicators:

Increased Throughput

Organizations implementing comprehensive batch record automation report throughput increases of 31% year-over-year while relying on the same resources—a direct result of reduced execution and review times.

Resource Optimization

Smart automation dramatically reduces busy work. One manufacturer saved over 250,000 hours through features like automatic calculations, conditional pathing, and automated signatures.

Working Capital Improvements

By reducing manufacturing lead times from weeks to days (or even hours!), you'll accelerate revenue recognition and reduce inventory costs, freeing capital for what matters most.

No paper.

No limits.

How MasterControl Manufacturing Excellence Makes It Possible

MasterControl Manufacturing Excellence (Mx) isn't just another electronic batch record system. It's a comprehensive platform specifically designed to help you implement smart automation strategies that work. The system delivers:

- Native automation features that eliminate 54%-81% of manual data entries.

- Seamless integrations with your equipment, enterprise resource planning (ERP) systems, learning information management systems (LIMS), and other key components of your existing tech stack.

- Risk-based exception review capabilities that dramatically reduce release times.

- Configuration flexibility that adapts to your workflows while enabling transformation.

- Validation-ready implementation that accelerates time to value.

Most importantly, MasterControl Mx lets you take a phased approach to automation, targeting high-impact areas first while building toward comprehensive digital transformation.

Your Path Forward: Where Quality Meets Efficiency

The competitive advantages of smart automation in life science manufacturing are undeniable. When you successfully implement strategic automation initiatives, you'll see significant improvements in efficiency, quality, and financial performance.

Your journey begins by identifying specific pain points and automation opportunities. Which manual processes cause the greatest delays? Where do errors most commonly occur? What integrations would deliver the highest value?

By answering these questions and embracing a digital-first mindset, you'll develop a roadmap to manufacturing excellence that delivers impressive returns while better serving patients and consumers through improved product availability and quality.

Ready to start your smart automation journey? Watch our on-demand webinar "Maximize ROI Through Smart Automation Strategies in Life Sciences Manufacturing" to learn from industry experts and develop your strategic approach to manufacturing excellence.

FREE RESOURCE

Enjoying this blog? Learn More.

Webinar: Maximize Life Sciences Manufacturing ROI Through Smart Automation Strategies

Watch Webinar