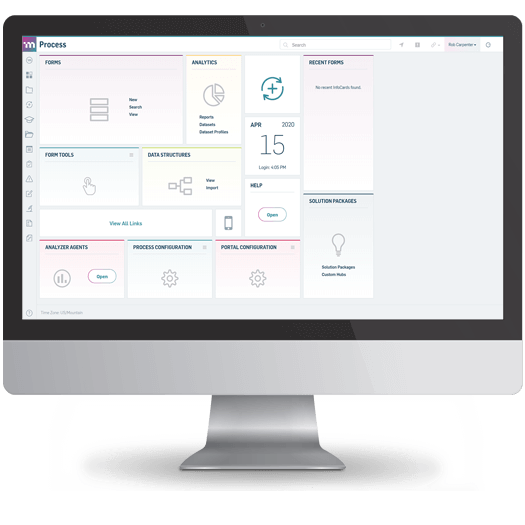

QMS Software for Manufacturing

A manufacturing quality management software system enables regulated manufacturers to get their products to market faster while simultaneously maintaining regulatory compliance. Furthermore, it allows cross-functional teams to efficiently collaborate on critical documents and accelerate the development cycle.